How to make a cheap soil moisture sensor

15.6 years ago cheap, electronics, water 112 Comments

Soil sensors can be pretty expensive to purchase but a few minutes and a few cents worth materials around your house you can make your own accurate cheap soil moisture sensor.

UPDATE: Though this still a great sensor, check this post for the latest version of a more heavy duty soil moisture sensor.

I mentioned in a previous post that my previous soil moisture sensor did not hold up in my automated grow box update, so I needed to make a new one. After a little research there was the classic science class method of creating a homemade sensor by simply putting two galvanized nails in the soil and measuring the resistance between them. A major problem with this solution is the soil composition can significantly vary the resistance and keeping the spacing between the nails could be troublesome.

After a little more research I came across the method that has been working well for over 50 years. This method includes taking two metal probes and inserting them into a gypsum block and measuring the resistance between them. The gypsum absorbs the water and provides a decent range of resistance and moisture measurement.

Unfortunately I was fresh out of gypsum (sort of), so I looked around the garage and found a good substitute, Plaster of Paris. Plaster of Paris is created by heating gypsum to around 150 degrees where it becomes calcium sulfate hemihydrate. After adding water and allowing to dry it magically turns back into gypsum with the added bonus it also has the ability to mold to any shape I could come up with . On to construction…..

Materials for cheap soil moisture sensor:

- 1 tsp Plaster of Paris

- 1/2 tsp cold water

- Disposable cup for mixing

- wide straw (I used one from McDonalds, but most fast food straws should work)

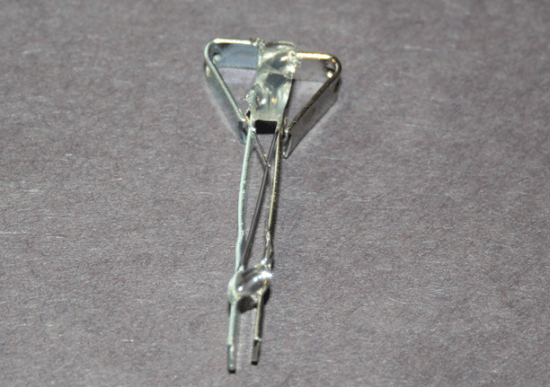

- 2 small pieces of metal (I used wall hangers, but nails, paper clips, etc will work as long as they can fit inside the straw with room for plaster to form around)

I straightened out one end of both wall hangers the best I could with some needle nose pliers. I then carefully positioned them approximated 15mm apart, the exact measurement is less important though if you are creating multiple sensors I would recommend making them the same gap to ensure consistency of measurements without having to individually calibrating each sensor. I then used some hot glue (insulator) liberally at the top and at the bottom just enough to keep it in place during while pouring the plaster and while the mold solidifies.

Now insert your secured metal probes into the straw, ensuring that both metal probes are equal distant from the sides of the straw. The great thing about the wall hangers is they do this automatically due to their wedge shape at the top. Once you have them centered apply gobs of glue to keep the probe in place but also to seal any gaps between the straw and the bottom of the straw. This needs to be water tight since this will be the bottom our your mold.

Prepare the Plaster of Paris according to the instructions on the box. On my box it said 2 parts mix to 1 part colder water. Given the small size of the mold 1 tsp of mix and 1/2 tsp of water which gave you more than enough to make one sensor. I used a bamboo skewer to stir since I would have gotten in trouble for trying to use our new silverware.

Now it is time to pour your mold, depending on how steady your hands are you should be able to pour the plaster right into the top of the straw. Fill about 1/4 of the length then tap the probe gently to help the plaster settle between the gaps. Repeat the previous step until the straw is full. If you have problems pouring you can also dip the skewer into the plaster and scrape it against the top edge of the straw. This step is optionally but I wanted to give my sensor a little point so I carefully added plaster beyond the end of the straw to provide a sharp point. Once you are done filling the straw, use your glue gun to secure the probe onto the paper you are working on and allow at least 1 hour to set.

After about an hour you can remove the bottom part of the probe. Do this by carefully cutting around the diameter of the bottom 3/4 of the straw, along with a lengthwise cut as shown in the lines marked above using a utility knife. You must be very careful in your cutting going too deep can result in cracking the plaster and you need to start all over.

Allow the plaster to dry for 24 hours and it should be ready for testing. With my probe it is essentially an insulator dry (beyond what my ohmmeter can measure) and a reading of 957 ohms when slightly damp which was a great range for measuring moisture level in my computerized grow box.

Finally, I attached attach wires to my analog measuring device (in my case a PS2 Controller) and I started getting readings. At this point you should calibrate the sensor by getting a reading with the probe dry then again when it is full saturated in water. Ironically, the probe I made was almost exactly specifications as the one I re-purposed from a cheap commercial soil moisture sensor so I didn’t even have to modify the constants on the automated computerized grow box software.

Given you can make hundreds of these things with a regular sized box of Plaster of Paris, box of paper clips and a few trips to your favorite fast food restaurant. The cost of each of these things would be pennies and given the cost of buying a commercial product seems like a very economical alternative.